As to baffle bags, the accessory designed by fibcmachinesworld enables continuous cutting by pulling the piece from the cutting machine to get a production cost-free finished piece, since the machine cuts it simultaneously with the usual cut.

Other accessories, such as double roll lifting device, edge guiding device, cold cutting (ideal for laminated fabric), turn it into the most complete configurable machine available on the market.

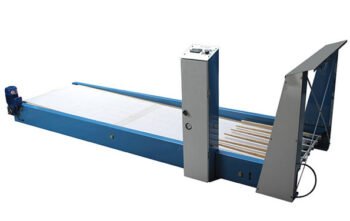

For throughput lower than 7000 Big Bags/month, we developed a semi-automatic cutting table [MC2000] that handles every cutting process both easily and inexpensively.