Automatic Bag Aligner.

Thread Cutting Sensor.

Mark Reading Sensor.

Cold/Hot Cutting.

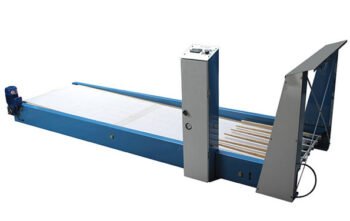

BAG MAKING MACHINE

This small sack making machine [CO800] performs the cutting and sewing process to deliver the finished bag.

Fabric unwinding, accumulation, cutting, transfer, hemming, sewing, thread cutting, and stacking, i.e., what is usually referred to as MANUFACTURE or PROCESSING LINE.

The transfer process (carrying the cut sack to the sewing area) is the greatest innovation in this unit:

Toothed synchronous belts with built-in grips make this operation easier, resulting in minimum consumption and maintenance free transfer. Only half a belt cycle is required to transfer the sack for subsequent sewing, leaving the device ready for the next sack. This avoids empty transfers for positioning purposes, as is the case with all transfer machines.

For manufacturers with a small throughput, we offer cutting machines with no transfer and sewing conveyor belts to minimize investment.

Automatic Bag Aligner.

Thread Cutting Sensor.

Mark Reading Sensor.

Cold/Hot Cutting.

CO800 CHARACTERISTICS

Max. bag width 730 mm

Max. bag length 1250 mm

Max. production rate 31 bags/min

Dimensions (length x width x height) 4450 x 3400 x 1600 mm

Weight 900 kg

Supply voltage 220 V / 380 V

Line frequency 50 Hz / 60 Hz

Total mechanical power 9.5 HP

Hot cutting transformer power 1.3 HP